02

Aug

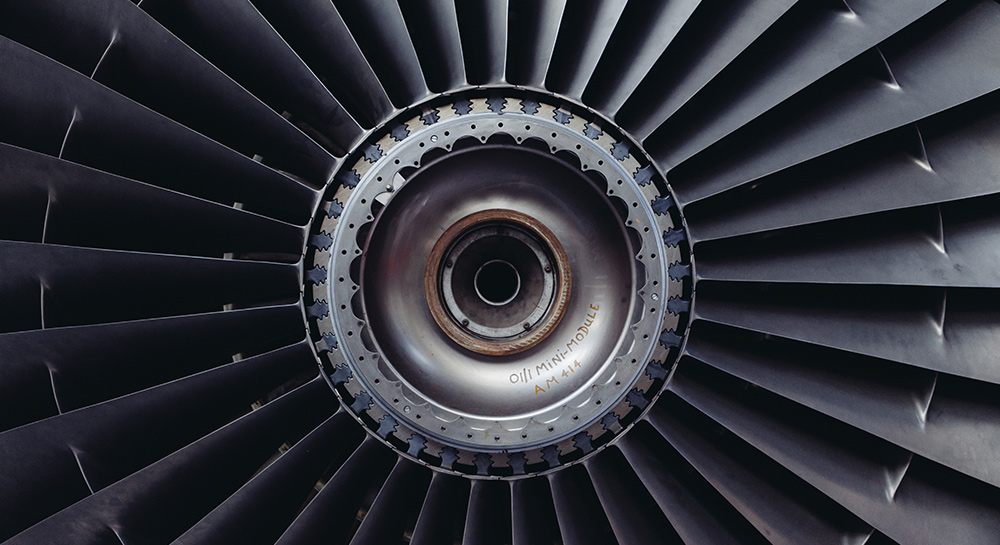

Case study - Technical Support

MISSION: TECHNICAL SUPPORT / ORGANISATION

Type of company: Global Group

Field of business: Aeronautics

Activity: Development, manufacture and distribution of engines and other equipment for the aeronautics industry

Issues: Implementation of two Lean management projects

Course of the mission:

1 full-time consultant / 14 weeks by project

Preliminary Phase:

- Definition of the perimeter

- Appointment of the sponsor

- Evaluation of the duration of the construction site

- Analysis of the major processes influencing the service/sector

Measurement Phase:

- Irritants, observations

- Focus group, VOC

- Process workshops

- Feedback from experience

- Evaluation of managerial practices

Analysis Phase:

- Valuation of the ‘waste’.

- Summary of the elements of the diagnosis

- Determination of the improvement plan

Improvement Phase:

- Deployment of the improvement plan with the lever drivers

- Setting up daily events with analysis of indicators

Control Phase:

- Follow-up of daily activities

- Verification of the achievement of the initial assumptions in terms of gains

Results: 15% gain in efficiency to iso-effectiveness